When it comes to commercial generator repair and complex engine difficulty one of your first calls should always be to Field Service Engineer (FSE) Mike, who has 42 years of experience and is EGSA certified.

Mike is one of the most decorated veterans of LionHeart having worked on virtually every type of generator imaginable. Whether it be an old Caterpillar or a brand-new Blue Star, Mike can help solve your problem and get your commercial generator running in tip top shape.

Extremely valuable as a mentor to many of LionHeart’s up and coming apprentices and newer journeymen, Mike excels as a Team Lead. He sets an example on how things should be done the LionHeart way.

What led you down the path to working on commercial generators?

I was born into it. My dad was a diesel mechanic in the Navy during World War 2. Many years later he worked at Western Engine Company. Ever since I was a little kid, I was around commercial generators and diesel engines because of him. I went to work in the office of Western Engine a couple days after I graduated high school. That was supposed to be my summer job before I started college at Arizona State. Life got in the way though because I met my wife Veronica that summer and the rest is history.

How did your role at Western Engine Company change over time?

Initially I was hired to work in the office. My father had worked his way to Vice President of Sales. I quickly realized I wasn’t wired for office work and went to the parts department and joined the Union. After that, I moved to the switchgear department to assist with production. Once the welding department built the enclosure, I’d stuff them with all the protective devices, controls and metering. Then our team would hand wire them and test them against generators. My last couple years were spent building enclosures for offshore oil platforms. Everything was explosion proof. Even though I was skilled at wiring, my goal was to get into the field. That is what I set my sights on.

You were at Patten – Caterpillar next, what did you learn during that experience?

They had a job opening for a build-up guy for power systems. I got the job, but made it clear I wanted to get into field service. After a year in the shop, I was moved out in the field. Back then you had a bunch of crabby old men working in the field. It isn’t like now. There was a huge age gap. You had to really prove yourself. You didn’t ask questions, just worked very hard to earn their respect. I was at Patten about 24 years.

You came to LionHeart in 2008, how did you get here? What attracted you to the company at first?

Don Ritter was doing field work and I ran into him a few times. Every time he bugged me about coming to LionHeart, but I was set on staying with CAT. As time went on, I wanted what LionHeart had, which was a smaller place with down to earth people. More independence. I finally decided to make the jump after a long discussion with Don and wish I had done it earlier as it’s been the best place I’ve worked.

How have generator technicians changed over the past thirty years?

Technicians today are typically younger and skilled with technology. They might not have the same amount of mechanical know-how, but they learn it. In the old days it was pretty much just mechanics that fought their way through electrical, today it is the opposite. Back in the day, you really had to pay your dues just to get in the field. Guys didn’t hustle like everyone does now. Mindset was taking your breaks, going out for your lunch. We’d get together and stop at a coffee house before jobs and get donuts. Nowadays a good field tech just wants to get the job done.

What things hamper the performance of a commercial generator?

Clients need to stay vigilant with their preventative maintenance schedule and testing. Many clients treat their generator like a sump pump or random piece of equipment. Just because your generator has worked in the past doesn’t mean it will work in the future if you aren’t keeping up with maintenance. Clients should run the unit once a month with load. You must load bank test at least once a year. Stay on top of the recommendations.

Back thirty years ago there weren’t many outside units. Now most buildings are being constructed with the generator(s) outdoors. When the unit is outside it invites animals, salt, dust, debris, you name it. When you open the enclosure door for an outside unit you have no idea what you’ll find, especially if a dumpster is nearby. Varmints are a big problem, especially in the winter. I’ve seen possums, raccoons, squirrels, pigeons, you name it, they’ll find a way in.

Why are Field Service Engineer recommendations so important?

An experienced Field Service Engineer can see issues and failures that are developing. Failures can cause the generator to be down when you need it the most. Clients might see it as nickel and diming, but part of our job is to find things that might need potential replacing. An experienced guy who has been around the block can detect and find things that will keep the generator running smooth and reliable when you need it the most.

What advice would you give a new Field Service Engineer in the back-up power industry?

Same advice I give myself every day. Slow down. Go slow and think things through. One thing I’ve harped on with the newer guys is to always double and triple check your work. The most important thing I’ve been told is, “don’t get excited.” If you get excited, you get confused, logic gets out the window and you’ll end up doing something wrong. You won’t be thinking clearly. I’ve always remembered that. Reach out to other techs because you aren’t alone. Ask questions. I’ve worked with tons of guys and everyone is happy to help. Everyone is here to help and may have already run into the issue you’re experiencing.

Wear your Personal Protective Equipment (PPE). Guys go to transfer switches all geared up which is great. We all see Kevin Sheppard wearing his arc flash suit, which sets a great example. That said, when you are hooking up to a load bank near the generator you are still at risk and should have your PPE on. Don’t get comfortable near a generator because there are plenty of dangers.

What traits do the best FSE’s seem to have in common?

The best field guys are smart, have an eye for detail, good retention and a strong work ethic. They continue to learn new things and are very interested in the work. The best FSE’s ask questions and keep distractions to a minimum.

You can’t PM and load test apprentices and newer journeymen to death. As you train, you must give them new challenges and throw them in the deep end so they can learn. Those big jobs that have a younger guy as a second wrench help them make accurate recommendations in the future. The field service team gets stronger when technicians get exposed to everything. The young guys want to prove themselves.

Les Tish is a younger FSE who won’t hesitate with new challenges. He’d do whatever job or task I ask him. No fear. He might not have done a certain job before, but he’ll jump right in and ask the right questions. Younger guys need that attitude. What an old boss said to me was, “you might not know anything about that issue now, but you will tomorrow.”

How has LionHeart changed over the past 12 years?

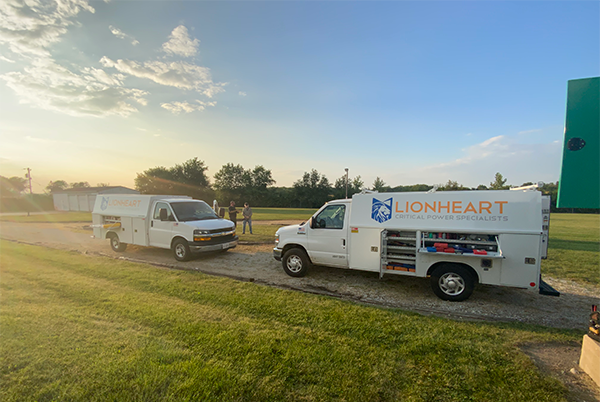

When I got here LionHeart was a tiny company in a tiny shop with not much of an office staff. There might have been six people in the office. I remember seeing 3-foot-tall stacks of papers on Don’s desk. Look what we have now. It is amazing. We keep growing and changing. The equipment we have is top notch. Our service vehicles look the best out of anyone.

What do you like most about working for LionHeart?

Everyone is just so down to earth. There is a great group of owners. The ownership is striving to grow, but also take care of everyone. Don feels a responsibility to everyone and treats his employees like family. I never got that anywhere else. There isn’t a wall between office staff and union, we work together. We can bounce ideas around. LionHeart is a well-oiled machine.

Here’s what our team members are saying about Mike:

Mike is one of the most well-respected technicians in the generator industry. He truly embodies LionHeart’s HERO core values of Honorable, Evolving, Responsible and One. Give me a team of Mike’s and we’ll rule the world.

Don Ritter, LionHeart President

Mike is always the same, consistent, happy guy each and every day. He’s very dependable and keeps to the task at hand and doesn’t over-react to obstacles. His cool, calm, very professional demeanor is insane. He is a true professional service technician.

Mike Hunter, LionHeart Vice President

Mike came out to perform our first test and was a true professional. He was on time, thorough and explained the next steps during the service. Mike even set up “camp” under a canopy when it started to drizzle so that he could continue with the inspection and PM service.

LionHeart Client

Learn more about the importance of commercial generator maintenance and repairs by contact us at 844-LHPOWER or [email protected].